ROLLAX POWDER

ROLLAX is a powdered cleaner which has been developed by MIZHO CHEMICAL CO.,LTD. to remove adhesive residue from operating surfaces of interlining fusing machines and irons. In addition, when used regularly, ROLLAX acts as a release agent, reducing further sticking of adhesive to operating surfaces and preserving teflon-coated belts and plates.

- Contains highly viscous silicone and improves mold release.

- Contains neither solvents nor poisonous chemicals and, when melting(60°C/140°F), does not release poisonous gases. Also, it does not damage machine surfaces or materials being fused.

- ROLLAX is not flammable under fusing conditions.

(Flash point:240°C/465°F; Ignition point:above 240°C/465°F.) - ROLLAX does not absorb humidity.

DIRECTIONS FOR USE

- ROLLAX produce an enough effect with little amount. Please be careful not to use too much. Overuse will be caused not only waste of material but also caused of trouble with residue.

- Melting Point of ROLLAX will be 60°C/140°F. Do not leave the ROLLAX on the fusing press or under the sun. Please store them in cool dark place.

Continuous Fusing Machines

- Allow the machine to reach operating temperature (120°C/250°F).

Note : The machine can be cleaned between operations also. - Remove cover plates and cleaning and stripping devices if necessary.

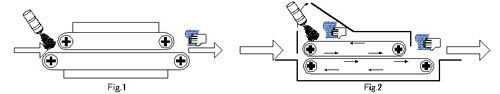

- Sprinkle ROLLAX evenly onto the heated Teflon belt while it is running. Allow time for ROLLAX to melt and spread over both belts, permeating the adhesive residue. (Refer to Fig.1 or Fig.2)

- While they are wet, wipe off the residue and excess ROLLAX from both belts with a cloth.

- To assure thorough cleaning, insert some sheets of pattern paper into the machine. Repeat the cleaning process and this test, if necessary, until no spots appear on test sheets.

- The machine is ready for operation.

Note : Use ROLLAX daily to maintain optimum operating conditions.

Flat Fusing Presses

- Allow the machine to reach operating temperature (120°C/250°F).

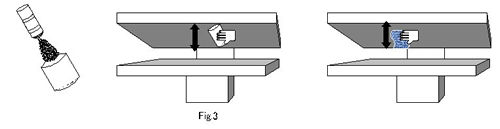

Note : The machine can be cleaned between operations also. - Put a small amount of ROLLAX into a cloth bag and rub the heating plate gently with this bag. (Refer to Fig.3) Allow time for ROLLAX to melt and permeate the adhesive residues.

- While the heating plate is still wet, wipe off the adhesive residue and excess ROLLAX with a cloth.

- To assure thorough cleaning, press a sheet of pattern paper in the machine. Repeat the cleaning process and this test, if necessary, until no spots appear on the test paper.

- The press is now ready for operation.

Note : Use ROLLAX daily to maintain optimum operating conditions.

CAUTION

Rollax Powder Beware of overseas counterfeit products!

Counterfeit Rollax Powder is being distributed overseas.

Please note that the quality is different!

HI-CLEAN Z

- HI-CLEAN Z is paste type of cleaning agent which removes hand scorches from the metal surface of irons and press machines.

- Consists of silicone, fine polishing powder and base cream, and does not contain poisonous chemicals and also does not release poisonous gases.

DIRECTIONS FOR USE

STICK-ACE

STICK-ACE is an iron cleaner to remove adhesive residue on iron surface.

Everyone can iron smoothly because of easy application.

- Easy to remove adhesive residue on iron surface.

- Smooth ironing for hand irons.

- No bad smell comes out during works.

- Small amount of STICK-ACE gets effective result.

- Safe for all metal and teflon-coated surface.

DIRECTIONS FOR USE

Wipe off all residue with a dry rug, while the iron surfaces still wet.

For heavy residue, cleaning must be repeated.

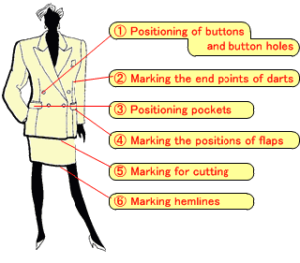

UV Fluorescent Marking

The ink only appears when illuminated under black light / UV light.

The ink is invisible under normal lighting or sunlight.

Can be used for fine or thick lettering according to the material to be marked.

Will easily mark material that is difficult to mark with a pencil or tailor’s chalk.

Suitable for marking white colored or thin parts where tailor’s chalk would be too conspicuous.

LUMI MARKER(Felt Pen Type)

Power supply:AC100V Specifications DIRECTIONS FOR USE

SUPER LUMI MARKER(Crayon Type)

(4Leads+holder+sharpener)

Black Light / UV Light

MIZHO Lumi Lite(ML91)

Weight:1.4kg(including UV lamp and clamp)

Power consumption:9W

Frequency:50/60Hz

MIZHO Lumi Lite(ML92)

Power supply:AC200V

Weight:1.4kg(including UV lamp and clamp)

Power consumption:9W

Frequency:50/60Hz

FUSE OUT

A releasing agent for fusible interlining that has been adhered in the incorrect position.

2.If the interlining does not peel off easily, lightly work the interlining with the hands, then peel it away.

* Dots from the fusible interlining may remain on the cloth; however, since the resin has been softened, these can be removed by rubbing the cloth with velvet or other napped material.

*Do not use with nylon-or acrylic-based cloth.

*Not effective against some types of adhesives, such as polyethylene resins, polyvinylchloride.

*Fuse-out contains organic solvents. Make sure that the workplace is sufficiently ventilated when applying Fuse-out in large amounts.

*Fuse-out contains no solvents or gas that will cause damage to the ozone layer.